The Technology

Exintech is an Australian innovation company with over 40 years experience in design and manufacture. Our expertise spans the product life cycle from concept inception through to material and production optimisation.

Exintech is an Australian innovation company with over 40 years experience in design and manufacture. Our expertise spans the product life cycle from concept inception through to material and production optimisation.

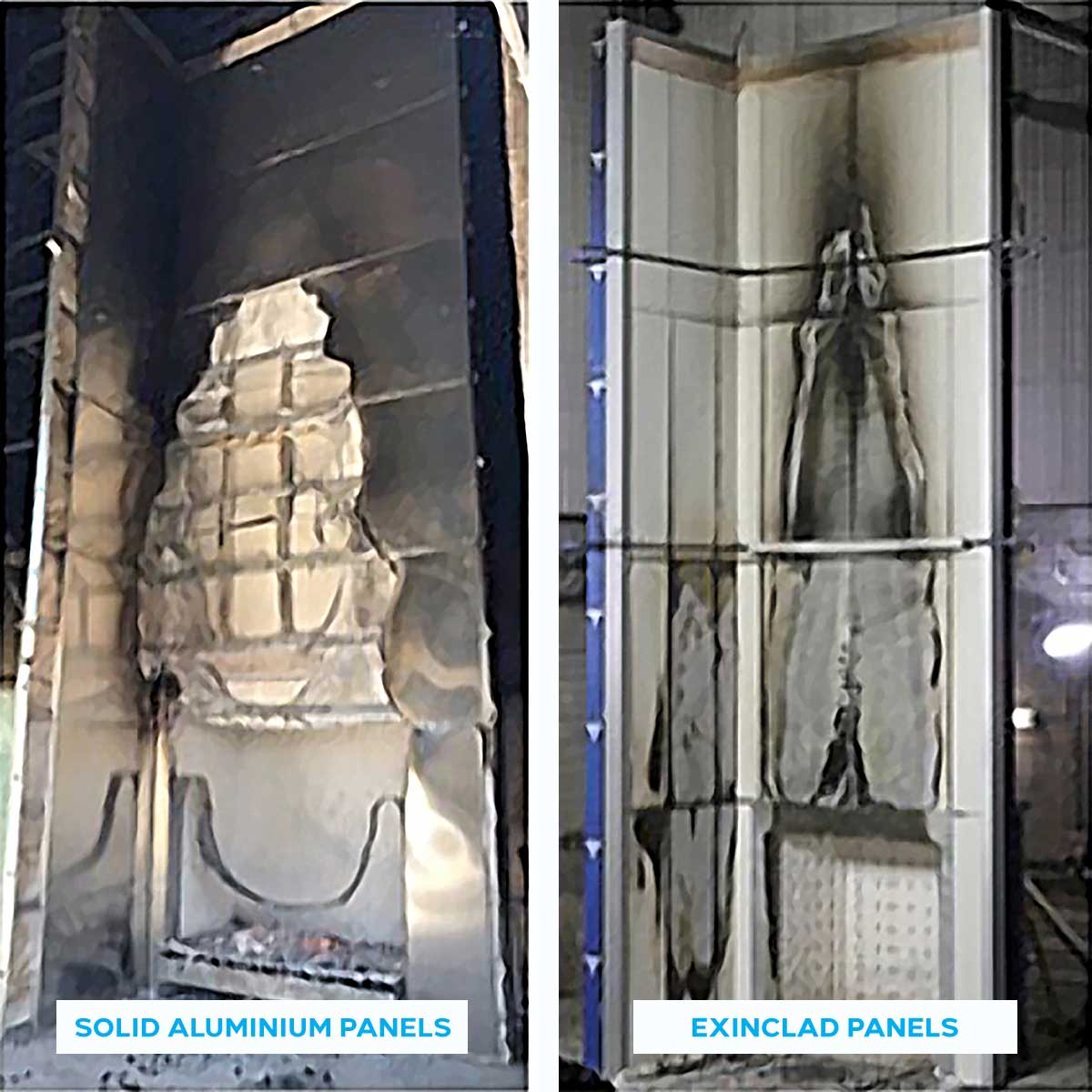

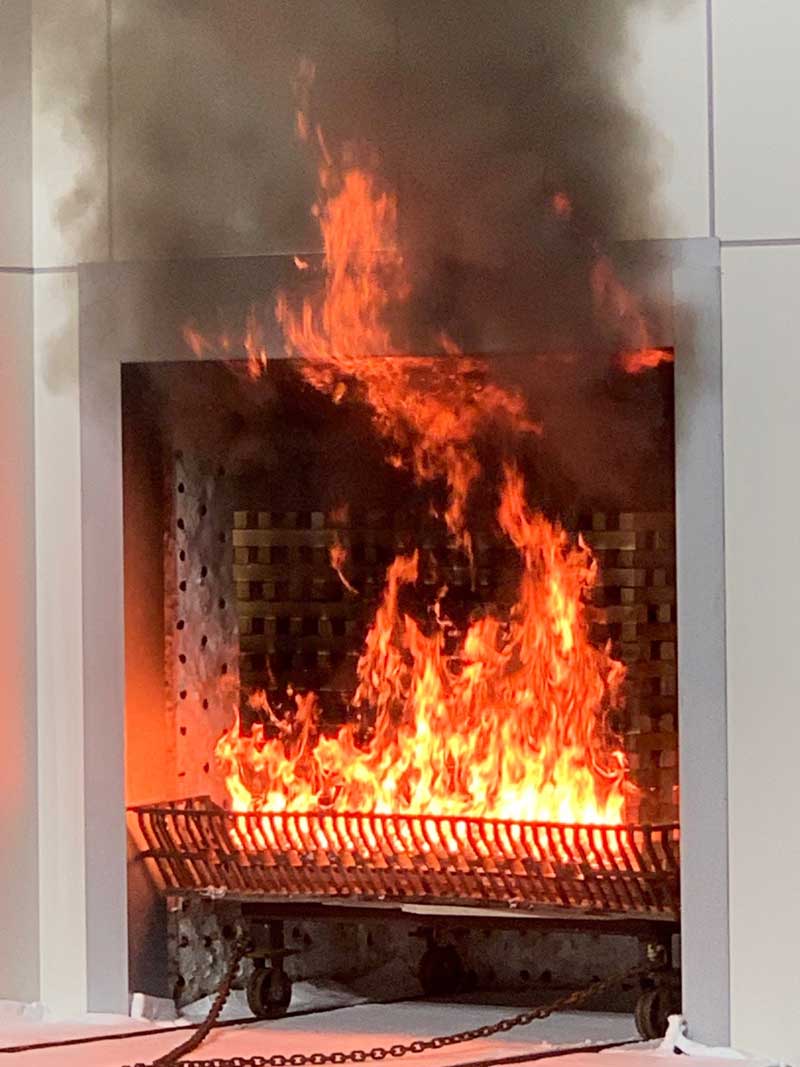

Exinclad®'s® fused steel panels being tested in the CSIRO's NATA accredited laboratory under the AS 5113 full scale fire test regime.

Fire-Resistant to withstand in excess of 1000°C

The only metal cladding that does not drop dangerous solid mass debris.

Heat Sink Technology to actively transfer and dissipate thermal energy.

5:15

mins

Flaming to surface coating at 650°C

Flaming to surface coating at 650°C

9:30

mins

Fire penetration of substrate at 1000 °C.

Vaporisation of coating at 1000°C.

13:45

mins

Fire intensifies beyond midlevel panels. Melting aluminium exceeds allowable 2kg. debris drop

Containment of fire spread due to resistance of zinc steel.

17:23

mins

Fire propagating underneath the mid and top-level panels. Panels open to reveal substrate

Abatement of flame due to protective zinc steel skin.

30:00

mins

Top panels dislodge. Mandatory termination of test.

Fire extinguished after mandatory 30 minutes: No smoke, No Flaming, No smouldering. All panels remain fastened. Surface damage only.

Exinclad® harnesses the lightness of aluminium with the strength and durability of steel to form a high-performance, high tensile, fire-resistant panel.

The patented combination of chemically fused zinc coated steel and aluminium utilizes industry-leading Heat Sink Technology to actively transfer and dissipate thermal energy. This uniquely enables Exinclad® to disperse heat and resist infernos in excess of 1,000 degrees Celsius.

Patented technology that chemically fuses zinc coated steel and aluminium to deliver the world’s safest metal cladding product – a high-performance, high-tensile, non-combustible façade panel that can withstand heat and flaming of up to 1,000 degrees Celsius.

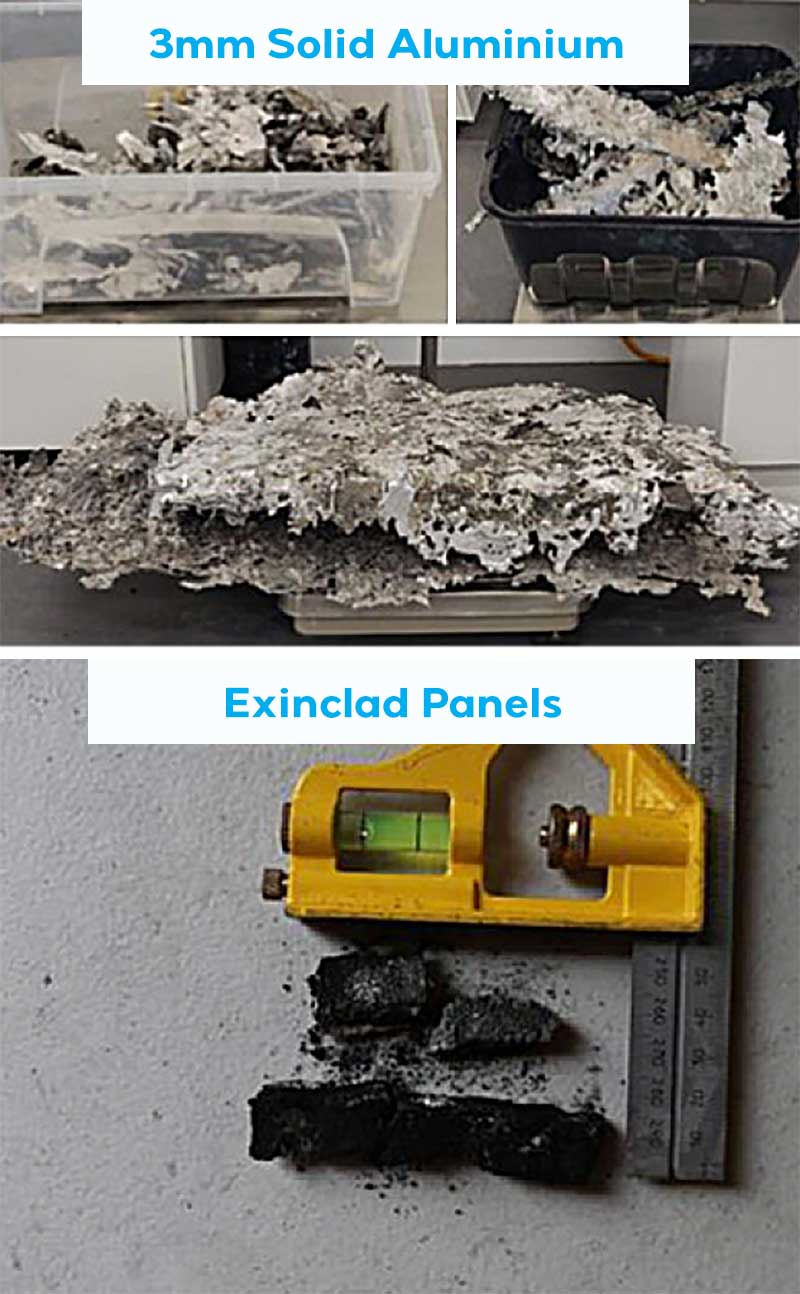

A total mass of debris exceeding 2.0 kg constitutes a failure of the debris criterion of AS 5113-2016.

3mm solid aluminium panel produced a total mass of 46kg (of which one piece weighed 19kg).

The Exinclad® panels satisfied this criterion with a total mass of under 100 grams.

Exinclad® harnesses the lightness of aluminium with the strength and durability of steel to form a high-performance, high tensile, fire-resistant panel.

“No other panel has passed the Debris Criterion of AS5113-2016 full scale fire test.”

“We have been using Aluminium façade materials for over 30 years and Exinclad® is the most innovative product we’ve come across in that time.”

“Exinclad® outperforms solid aluminium, and is the only aluminium based façade panel I have ever seen that passes the debris criteria of AS5113.”

We would like to hear from you.